Oxygen Generators

Discover the production of oxygen gas with Nitroxtec’s superior quality and modern technology. PSA technology is applied in the separation of oxygen gas from compressed air.

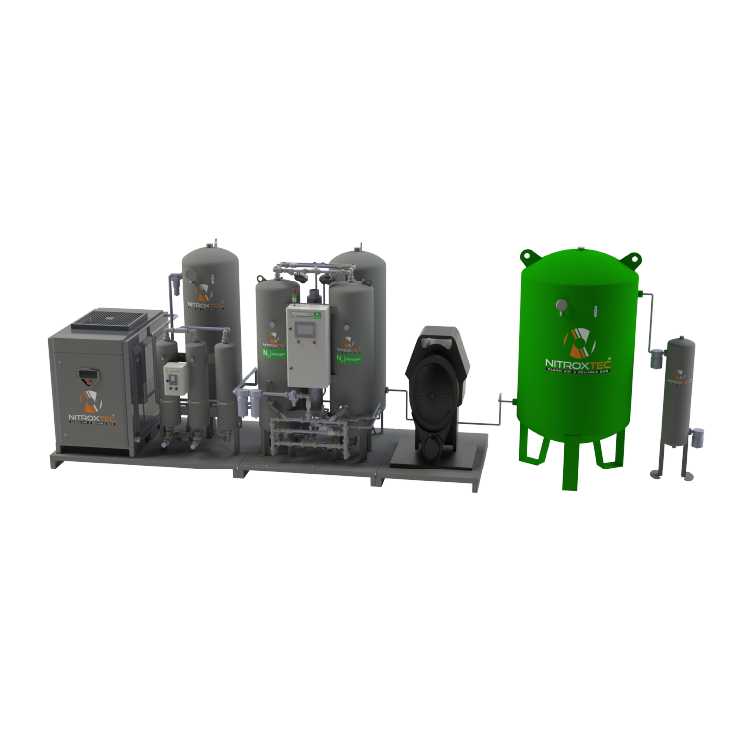

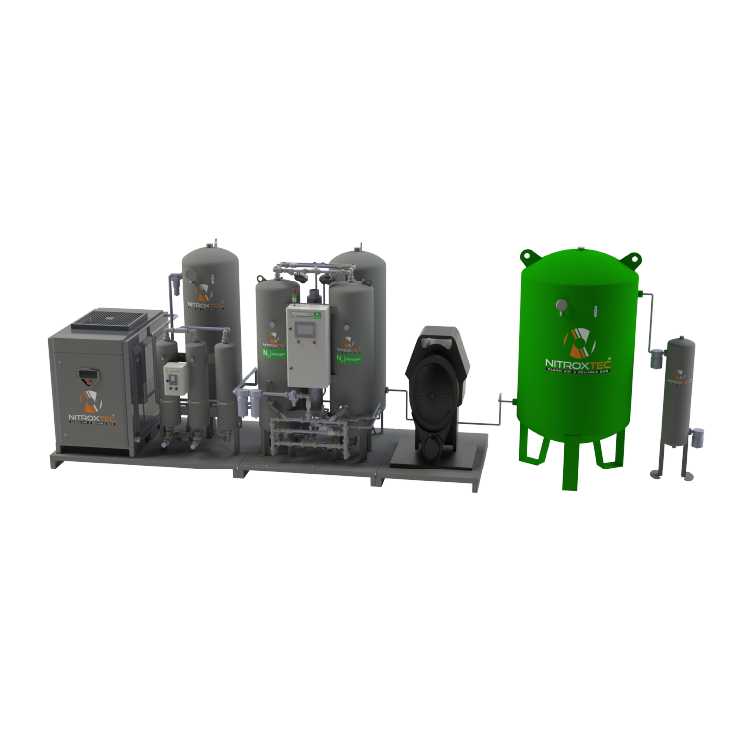

Nitrogen Generators

It is designed to ensure maximum performance and continuous production of nitrogen gas. It is manufactured with advanced technology. It operates using the PSA (Pressure Swing Adsorption) process.

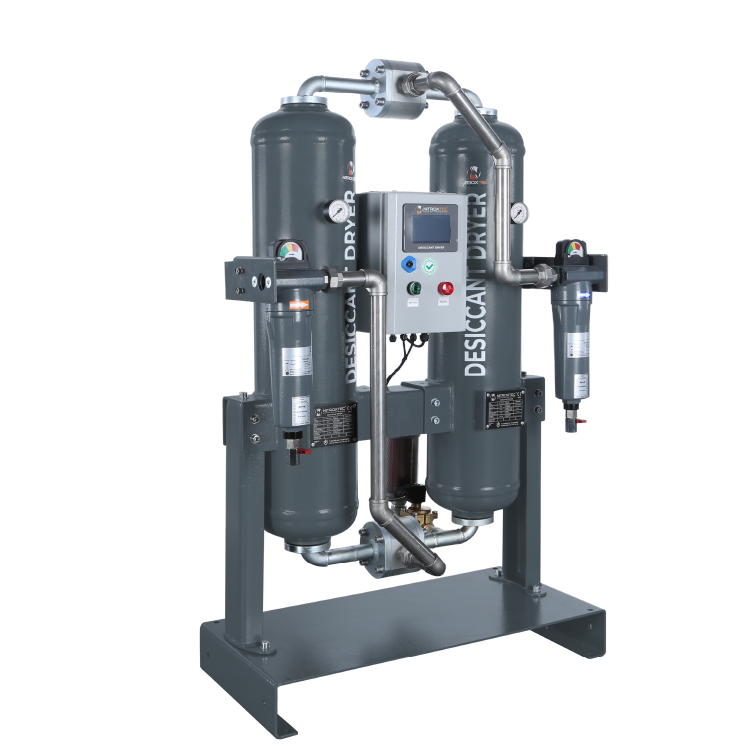

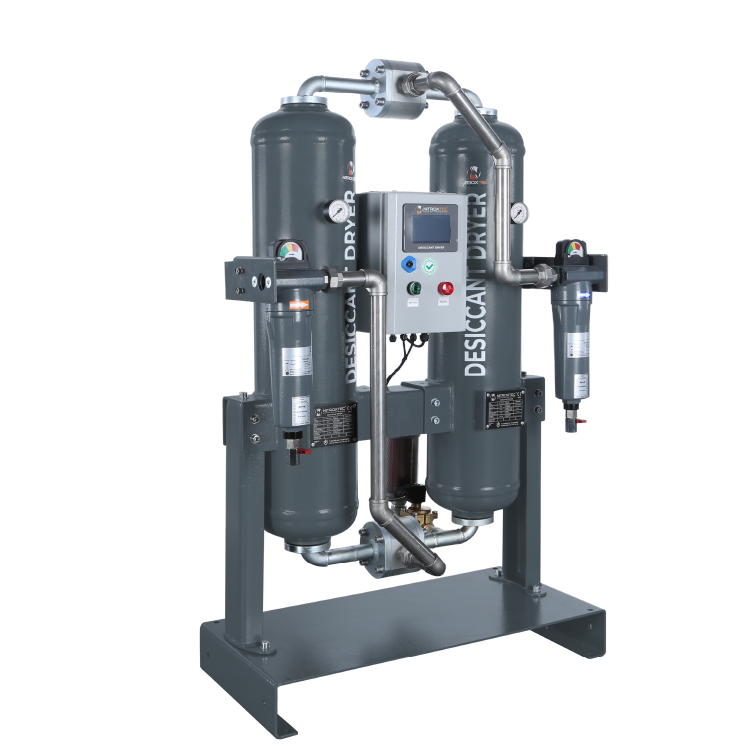

Desiccant Dryers

Modern technology is used to produce synthetic adsorbents, activated alumina, silica gel, and molecular sieves for drying and purifying air for industrial solutions.

Heated Type Blower Desiccant Air Dryers

It provides energy savings through regeneration with outside air. These systems, which offer a low dew point of up to 1%, are ideal for high flow and continuously operating facilities.

Modular Oxygen Generators

Modular Type Oxygen Generators are designed with a flexible structure to meet varying oxygen needs. They provide continuous, safe, and high-purity oxygen production with Nitroxtec technology.

Modular Nitrogen Generators

These generators, utilising advanced PSA (Pressure Swing Adsorption) technology, provide high-purity nitrogen with their compact and modular design, offering continuous and reliable nitrogen supply for numerous industrial applications.

High Pressure Desiccant Dryers

Nitroxtec Non-Heating High-Pressure Chemical Air Dryers provide ultra-dry compressed air with a dew point of -40 °C or -70 °C, depending on application requirements.

Oilless Desiccant Dryers

The chemical dryer and activated carbon tower complement each other. This allows for the production of high-quality oil-free dry air. NitroxTec chemical dryers integrated with activated carbon are equipped with special valves and high-quality moisture and oil traps.

Activated Carbon Tower Filters

Activated Carbon Tower Filters effectively remove oil vapour, odours, and organic pollutants from compressed air systems. Offered with the assurance of Nitroxtec, the Activated Carbon Tower Filters enable you to obtain high-purity air.

NITROXTEC Gas-Cooled Air Dryers

Gas-Cooled Air Dryers prevent condensation in your compressed air systems with high-efficiency cooling technology, providing dry and high-quality air. They offer energy-saving and reliable solutions with the assurance of Nitroxtec.

High Pressure Oil-Free Chemical Air Dryers

NitroxTec oil-free chemical air dryers are produced for applications that require very dry compressed air and oil-free air. The chemical dryer and the activated carbon tower complement each other.

High Pressure Activated Carbon Tower Filters

Nitroxtec High-Pressure Activated Carbon Tower Filters efficiently remove oil vapours, odours, and hydrocarbons from compressed air at pressures of up to 300 bar.

Containerised Nitrogen Production System

Container-type nitrogen production systems are among the most preferred nitrogen production systems due to their flexibility in meeting needs and simple installation. Thanks to their portable and ready-to-use features, container-type nitrogen production systems are an excellent solution for businesses.

Modular Desiccant Air Dryers

Modular Type Chemical Air Dryers provide reliable drying performance in compressed air lines with their compact design saving floor space and low dew point. They ensure continuous and energy-efficient operation with Nitroxtec quality.

Modular Type Oil-Free Desiccant Air Dryers

Modular type oil-free chemical air dryers provide maximum dryness and high efficiency in your compressed air systems. Their oil-free design makes them ideal for critical applications. They offer safe, compact, and energy-saving solutions with Nitroxtec quality.

Modular Type Activated Carbon Tower Filters

NitroxTec Modular Type Activated Carbon Towers are designed to separate oil vapour found in compressed air from the compressed air itself. The tower features flow distribution diffusers at both the inlet and outlet. The activated carbon in the system has been designed with careful consideration for the equal and homogeneous distribution of air flow.

Containerised Oxygen Production System

Modular Type Oxygen Generators are designed with a flexible structure to meet varying oxygen needs. They provide continuous, safe, and high-purity oxygen production with Nitroxtec technology.

Automatic Mixed Gas Production Systems for NitroMix Laser Cutting Machines (25-40 BAR)

These generators, utilising advanced PSA (Pressure Swing Adsorption) technology, provide high-purity nitrogen with their compact and modular design, offering continuous and reliable nitrogen supply for numerous industrial applications.

NITROPLACE Nitrogen Gas Production and Storage Systems for Laser Cutting (230–300 BAR)

Nitroxtec Non-Heating High-Pressure Chemical Air Dryers provide ultra-dry compressed air with a dew point of -40 °C or -70 °C, depending on application requirements.

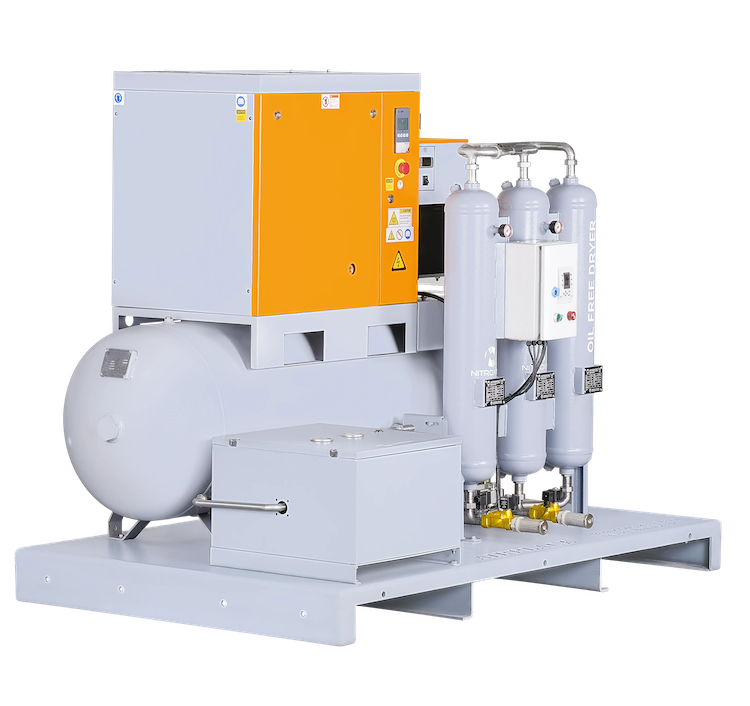

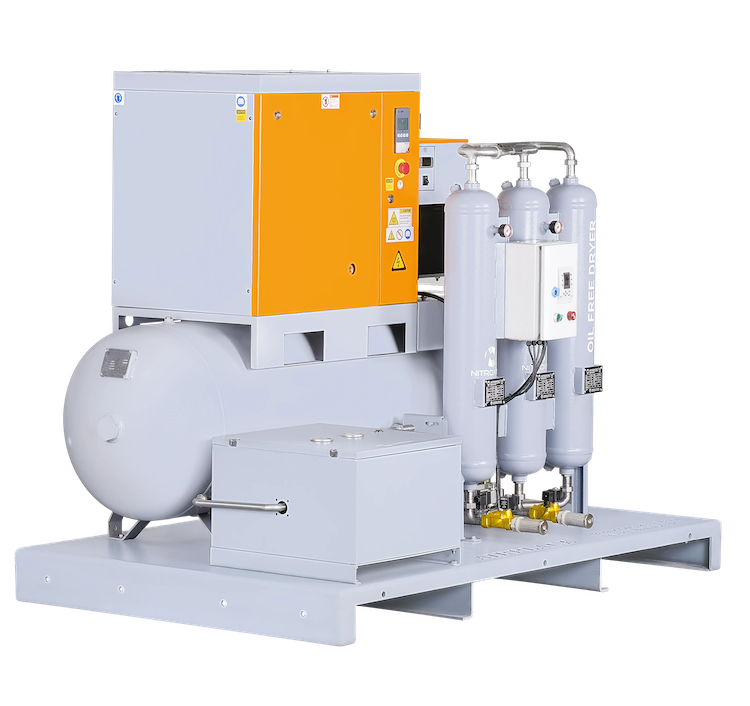

AIRPLACE Oil-Free Pressurised Dry Air Systems for Laser Cutting Machines (13 – 25 BAR)

The chemical dryer and activated carbon tower complement each other. This allows for the production of high-quality oil-free dry air. NitroxTec chemical dryers integrated with activated carbon are equipped with special valves and high-quality moisture and oil traps.

Containerised Oxygen Production System

Container-type oxygen production systems are among the most preferred oxygen production systems due to their flexibility in meeting needs and simple installation. Container-type oxygen production systems are an excellent solution for businesses thanks to their portable and ready-to-use features.

Automatic Mixed Gas Production Systems for NitroMix Laser Cutting Machines (25-40 BAR)

Nitroxtec NitroMix Automatic Mixture Gas Production Systems (25–40 BAR) offer a smart, energy-saving, and economical alternative to traditional nitrogen supply for fibre laser cutting machines.

NITROPLACE Nitrogen Gas Production and Storage Systems for Laser Cutting (230–300 BAR)

It guarantees precise, oxidation-free cutting results in all types of metals, including stainless steel, aluminium, copper, chrome, and galvanised sheet metals, by providing nitrogen at a purity of 99.99% to 99.999% and at a pressure of 230–300 BAR.

AIRPLACE Oil-Free Pressurised Dry Air Systems for Laser Cutting Machines (13 – 25 BAR)

AIRPLACE, which has high compatibility with various materials such as carbon steel and aluminium, offers an economical and efficient alternative to nitrogen or oxygen cutting gases. It provides the most ideal solution with its plug-and-play ease of use and efficiency.

Carbon Molecular Sieve CMS

Nitroxtec CMS (Carbon Molecular Sieve) is the primary adsorption material used in PSA nitrogen generators. This material enables the separation of nitrogen from compressed air with a purity of up to 99.9999%.

Zeolite

Nitroxtec uses high-quality Zeolite Molecular Sieves as the primary adsorption material for PSA Oxygen Generators and provides efficient oxygen separation from compressed air.

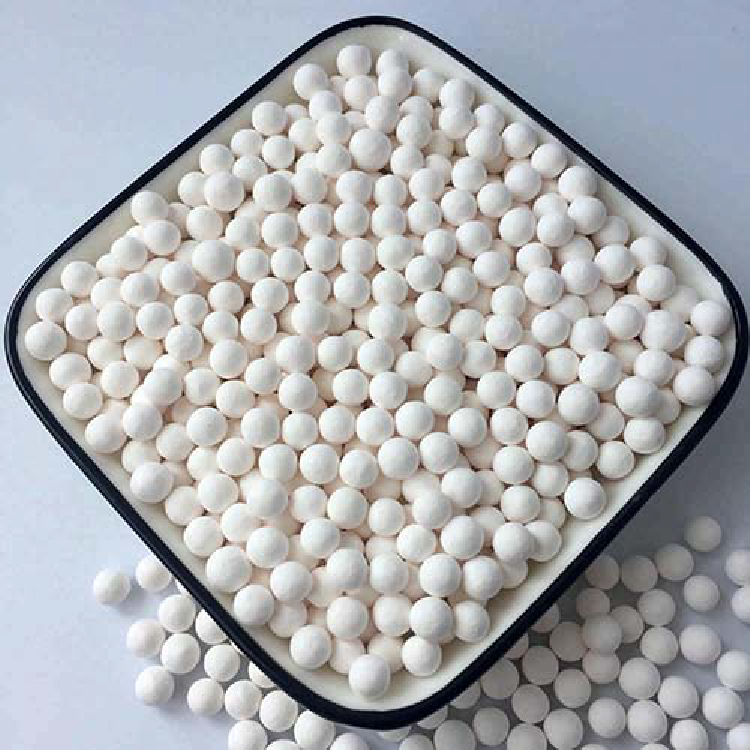

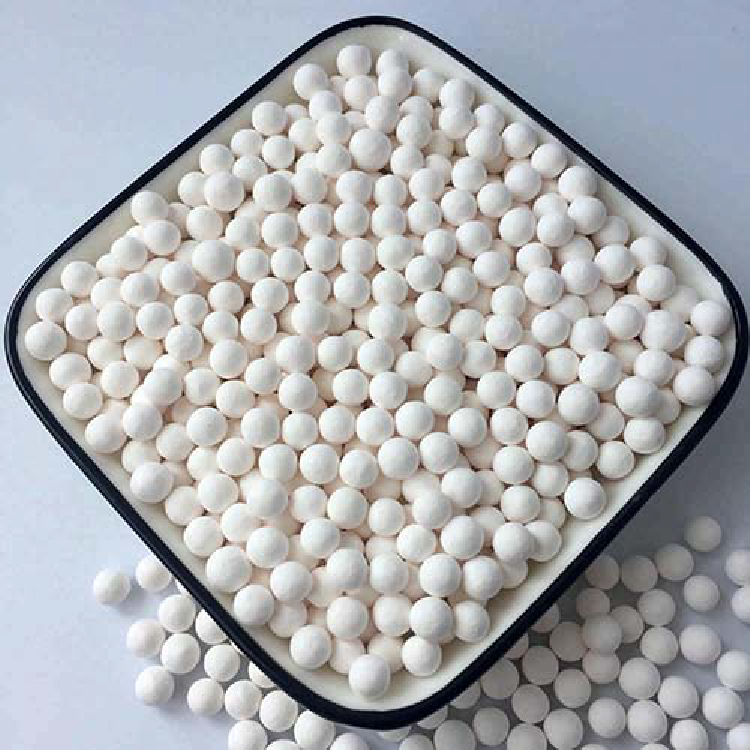

Active alumina & Silica alumina gel

Nitroxtec uses high-quality Activated Alumina as the primary drying medium in its Dehumidifier systems.

Activated Carbon

Nitroxtec Coconut Shell Activated Carbon is a high-performance adsorbent material designed to efficiently remove oil vapours, odours, and hydrocarbons in compressed air purification systems.

Oxygen Generators

Discover the production of oxygen gas with Nitroxtec’s superior quality and modern technology. PSA technology is applied in the separation of oxygen gas from compressed air.

Nitrogen Generators

It is designed to ensure maximum performance and continuous production of nitrogen gas. It is manufactured with advanced technology. It operates using the PSA (Pressure Swing Adsorption) process.

Desiccant Dryers

Modern technology is used to produce synthetic adsorbents, activated alumina, silica gel, and molecular sieves for drying and purifying air for industrial solutions.

Heated Type Blower Desiccant Air Dryers

It provides energy savings through regeneration with outside air. These systems, which offer a low dew point of up to 1%, are ideal for high flow and continuously operating facilities.

Modular Oxygen Generators

Modular Type Oxygen Generators are designed with a flexible structure to meet varying oxygen needs. They provide continuous, safe, and high-purity oxygen production with Nitroxtec technology.

Modular Nitrogen Generators

These generators, utilising advanced PSA (Pressure Swing Adsorption) technology, provide high-purity nitrogen with their compact and modular design, offering continuous and reliable nitrogen supply for numerous industrial applications.

High Pressure Desiccant Dryers

Nitroxtec Non-Heating High-Pressure Chemical Air Dryers provide ultra-dry compressed air with a dew point of -40 °C or -70 °C, depending on application requirements.

Oilless Desiccant Dryers

The chemical dryer and activated carbon tower complement each other. This allows for the production of high-quality oil-free dry air. NitroxTec chemical dryers integrated with activated carbon are equipped with special valves and high-quality moisture and oil traps.

Activated Carbon Tower Filters

Activated Carbon Tower Filters effectively remove oil vapour, odours, and organic pollutants from compressed air systems. Offered with the assurance of Nitroxtec, the Activated Carbon Tower Filters enable you to obtain high-purity air.

NITROXTEC Gas-Cooled Air Dryers

Gas-Cooled Air Dryers prevent condensation in your compressed air systems with high-efficiency cooling technology, providing dry and high-quality air. They offer energy-saving and reliable solutions with the assurance of Nitroxtec.

High Pressure Oil-Free Chemical Air Dryers

NitroxTec oil-free chemical air dryers are produced for applications that require very dry compressed air and oil-free air. The chemical dryer and the activated carbon tower complement each other.

High Pressure Activated Carbon Tower Filters

Nitroxtec High-Pressure Activated Carbon Tower Filters efficiently remove oil vapours, odours, and hydrocarbons from compressed air at pressures of up to 300 bar.

Containerised Nitrogen Production System

Container-type nitrogen production systems are among the most preferred nitrogen production systems due to their flexibility in meeting needs and simple installation. Thanks to their portable and ready-to-use features, container-type nitrogen production systems are an excellent solution for businesses.

Modular Desiccant Air Dryers

Modular Type Chemical Air Dryers provide reliable drying performance in compressed air lines with their compact design saving floor space and low dew point. They ensure continuous and energy-efficient operation with Nitroxtec quality.

Modular Type Oil-Free Desiccant Air Dryers

Modular type oil-free chemical air dryers provide maximum dryness and high efficiency in your compressed air systems. Their oil-free design makes them ideal for critical applications. They offer safe, compact, and energy-saving solutions with Nitroxtec quality.

Modular Type Activated Carbon Tower Filters

NitroxTec Modular Type Activated Carbon Towers are designed to separate oil vapour found in compressed air from the compressed air itself. The tower features flow distribution diffusers at both the inlet and outlet. The activated carbon in the system has been designed with careful consideration for the equal and homogeneous distribution of air flow.

Containerised Oxygen Production System

Modular Type Oxygen Generators are designed with a flexible structure to meet varying oxygen needs. They provide continuous, safe, and high-purity oxygen production with Nitroxtec technology.

Automatic Mixed Gas Production Systems for NitroMix Laser Cutting Machines (25-40 BAR)

These generators, utilising advanced PSA (Pressure Swing Adsorption) technology, provide high-purity nitrogen with their compact and modular design, offering continuous and reliable nitrogen supply for numerous industrial applications.

NITROPLACE Nitrogen Gas Production and Storage Systems for Laser Cutting (230–300 BAR)

Nitroxtec Non-Heating High-Pressure Chemical Air Dryers provide ultra-dry compressed air with a dew point of -40 °C or -70 °C, depending on application requirements.

AIRPLACE Oil-Free Pressurised Dry Air Systems for Laser Cutting Machines (13 – 25 BAR)

The chemical dryer and activated carbon tower complement each other. This allows for the production of high-quality oil-free dry air. NitroxTec chemical dryers integrated with activated carbon are equipped with special valves and high-quality moisture and oil traps.

Containerised Oxygen Production System

Container-type oxygen production systems are among the most preferred oxygen production systems due to their flexibility in meeting needs and simple installation. Container-type oxygen production systems are an excellent solution for businesses thanks to their portable and ready-to-use features.

Automatic Mixed Gas Production Systems for NitroMix Laser Cutting Machines (25-40 BAR)

Nitroxtec NitroMix Automatic Mixture Gas Production Systems (25–40 BAR) offer a smart, energy-saving, and economical alternative to traditional nitrogen supply for fibre laser cutting machines.

NITROPLACE Nitrogen Gas Production and Storage Systems for Laser Cutting (230–300 BAR)

It guarantees precise, oxidation-free cutting results in all types of metals, including stainless steel, aluminium, copper, chrome, and galvanised sheet metals, by providing nitrogen at a purity of 99.99% to 99.999% and at a pressure of 230–300 BAR.

AIRPLACE Oil-Free Pressurised Dry Air Systems for Laser Cutting Machines (13 – 25 BAR)

AIRPLACE, which has high compatibility with various materials such as carbon steel and aluminium, offers an economical and efficient alternative to nitrogen or oxygen cutting gases. It provides the most ideal solution with its plug-and-play ease of use and efficiency.

Carbon Molecular Sieve CMS

Nitroxtec CMS (Carbon Molecular Sieve) is the primary adsorption material used in PSA nitrogen generators. This material enables the separation of nitrogen from compressed air with a purity of up to 99.9999%.

Zeolite

Nitroxtec uses high-quality Zeolite Molecular Sieves as the primary adsorption material for PSA Oxygen Generators and provides efficient oxygen separation from compressed air.

Active alumina & Silica alumina gel

Nitroxtec uses high-quality Activated Alumina as the primary drying medium in its Dehumidifier systems.

Activated Carbon

Nitroxtec Coconut Shell Activated Carbon is a high-performance adsorbent material designed to efficiently remove oil vapours, odours, and hydrocarbons in compressed air purification systems.